Our team is currently building resources in Morocco where we are preparing to launch the next phase of our field trial. This week our Moroccan team visited COPAG, one of Morocco's premier dairy cooperatives, to learn more about their milk sourcing operations. COPAG works with 14,000 diary producers throughout the country, which range from large dairy farms to individual families with only 1 or 2 cows. COPAG is in the Souss Massa Draa region of Morocco, the country's leading producer of tomatoes and dairy products, but also one of the least economically developed regions in the country. Experiences like our visit to COPAG give us a better sense of community needs and afford us opportunities to forge partnerships with organizations seeking to improve the lives of the rural poor.

We got mentioned on Conan!

Must Read: New York times article on African Spoilage

The New York Times just published a fantastic article titled Wasting Less of Africa’s Harvest in Order to Prosper. The article looks at multiple angles of the problem of post harvest spoilage in Tanzania and what the government and people are doing to combat it. Evaporative coolers are mentioned as one piece of the solution and reminds all of us here at Evaptainers why it is so important that we develop and deploy our product. Read the article and learn more about our mission to reduce food waste and improve food security.

Evaptainers Featured in CNN Money

We are so pleased to be recognized by the team at CNN Money for our work in alternative refrigeration. It is media exposure like this that will help us bring our technology to market. If you want to be kept up to date about our progress please fill out our contact form and you will be added to our mailing list.

- The Evaptainer Team

Back in the blog world

Evaptainers featured in Big Picture Agriculture

Big Picture Agriculture, a really well done farming and industry blog, posted a little synopsis of our work to date. We always like getting noticed by great people in the space. As we work towards introducing our product to market it is really edifying to see how many people see the value and need for this even at such an early stage.

The Science of Evaporative Cooling

Evaporative cooling is something that we have all experienced. Wearing a damp tee shirt on a warm but windy day gives us a chill. The phenomenon that causes this is the latent heat of vaporization.

What does this mean?

At critical temperature points in the diagram (0 degrees Celsius and 100 degrees Celsius) water needs to draw in heat energy from the environment to change phase. In order to melt or evaporate the water requires energy from the environment: this is the latent heat of vaporization.

Current research (Jozsef Garai, 2009) suggests that the energy required to free an atom from the liquid is equivalent to the energy needed to overcome the surface resistance of the liquid. You may remember from school that water has relatively high surface tension from its hydrogen bonds, thus water needs to absorb a large amount of energy to go through a phase change.

The reason we care about this in terms of evaporative cooling is that the more energy that water draws the more we can cool the contents of our Evaptainer. By the numbers this shakes out to 1g of evaporated water reducing the temperature of 1kg of water by half a degree Celsius. However, this assumes 100% efficiency. Evaporative coolers are typically slightly less efficient than this (60-80% efficiency).

What impacts this rate of efficiency is ambient conditions or "Wet Bulb to Dry Bulb."

What does that mean?

psychRometric chart - Don't worry if it looks confusing, it is.

The potential for evaporative cooling depends on the difference in wet bulb and dry bulb temperatures of the air. Humid air has a high relative humidity, and not as much capability to evaporate moisture. As the relative humidity of the air increases, the performance of the system will decrease, limiting its application in moist climates. Evaporative cooling is most effective in climates where average relative humidity is less than 30%. As humidity increases, and the cooling capability declines, the temperature difference between the outside and inside of the chamber decreases. To test if evaporative cooling will be effective, the wet bulb temperature can be measured by placing a moist cloth on the end of a thermometer and waving it through the air. The temperature read by the thermometer is the theoretical minimum temperature that can be achieved through evaporative cooling. For a visual representation of this phenomenon we can use psychometric charts. psychometric charts are a useful tool for predicting a particular wet-bulb temperature given the outside ambient conditions: pressure, temperature, and humidity.

Above and beyond pyschometric charts (which only have 3 variables), anything that increases the rate of evaporation of a system will make evaporative cooling more effective.

This includes:

- Lowering ambient humidity

- Decreasing atmospheric pressure

- Increasing ambient temperature (though this one is obviously counterproductive)

- Increasing surface area of evaporation

- Choosing different evaporative media

- Adding air movement/wind

Using all of these variables we are able to optimize the cooling effect of our system across the widest range of applications.

Learn more about our product that harnesses these phenomena.

Testing and Progress

The Evaptainers team is busy working on our field test prototype for deployment this fall.

At this stage of development our work is organized along two main tracks. The first is materials testing. The efficiency of our product will largely depend on the make up of the evaporative medium we use to draw heat out of the unit and dissipate it via evaporation. We are testing fabrics, granulates and foams to find the perfect balance of evaporation rate, weight and stiffness.

The other work track is 3d modeling. Our design team is creating the unit in 3D space and defining how the various elements of the unit will interact to give us the best possible product. It is an exciting process to watch and to see where concept and execution meet.

While this work on the product is progressing we are also laying the ground work for our first Coop field trial in Morocco that will take place in the next 6 months.

Stay tuned as we continue to finalize the form and function of the Evaptainer.

Evaptainers in the Boston Herald

We could not be more pleased to be featured in today's edition of the Boston Herald! In the article titled Cool Idea for Saving Produce the Herald highlights the technology, the company and our progress in building our first field test unit. We would like to thank the Herald and MassChallenge for this exposure and the boost it give us as we work to bring this new technology to the world.

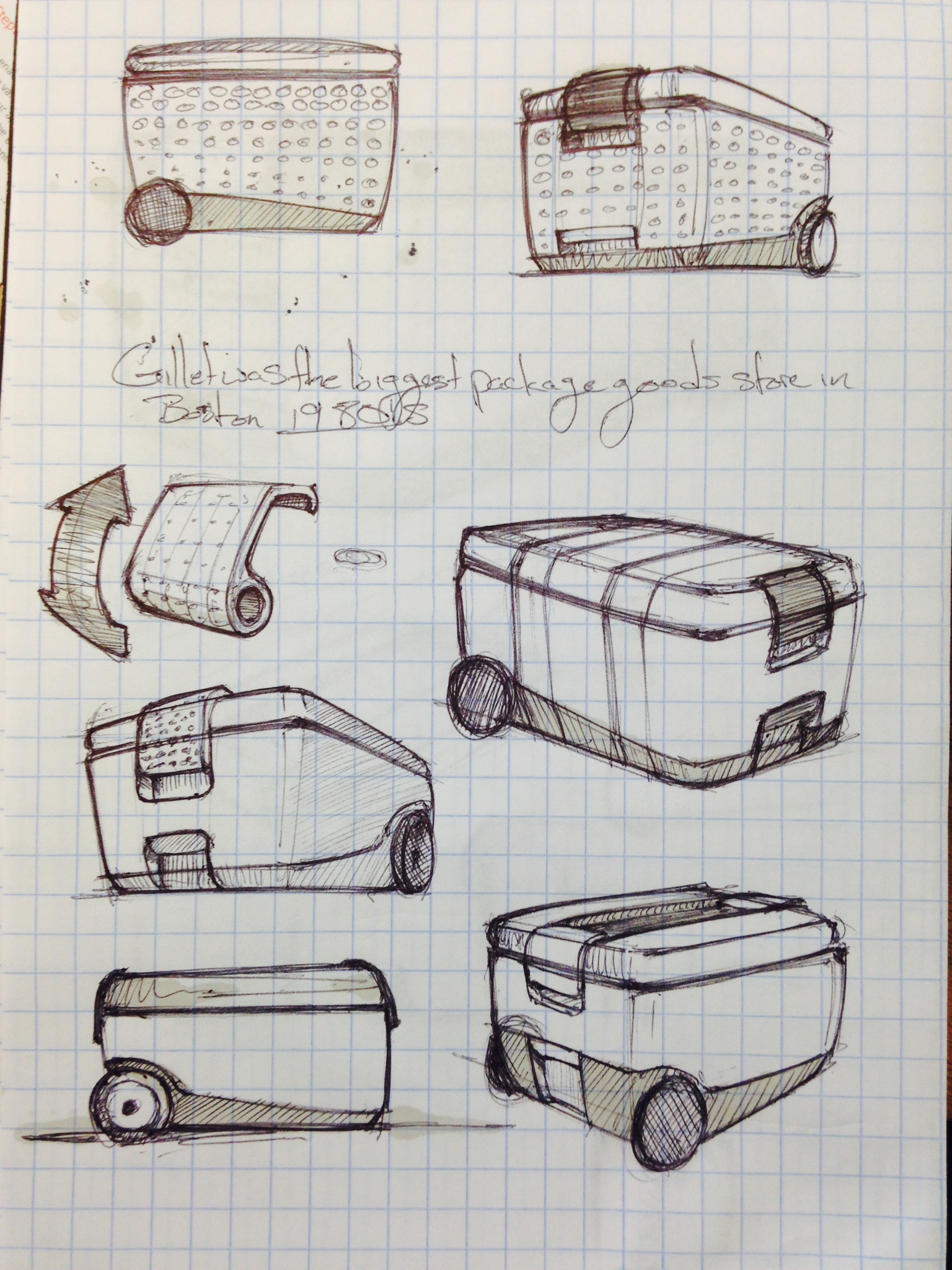

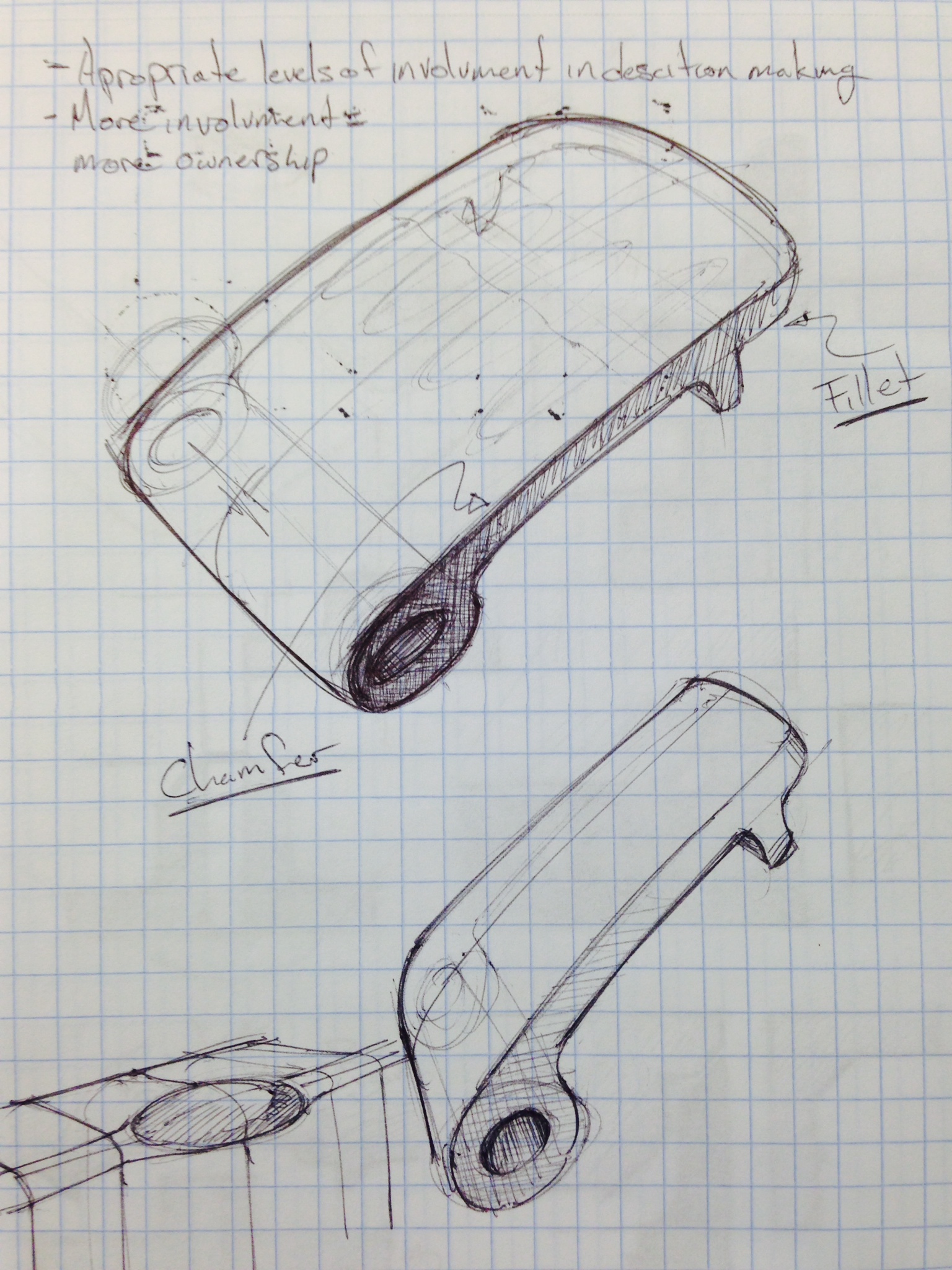

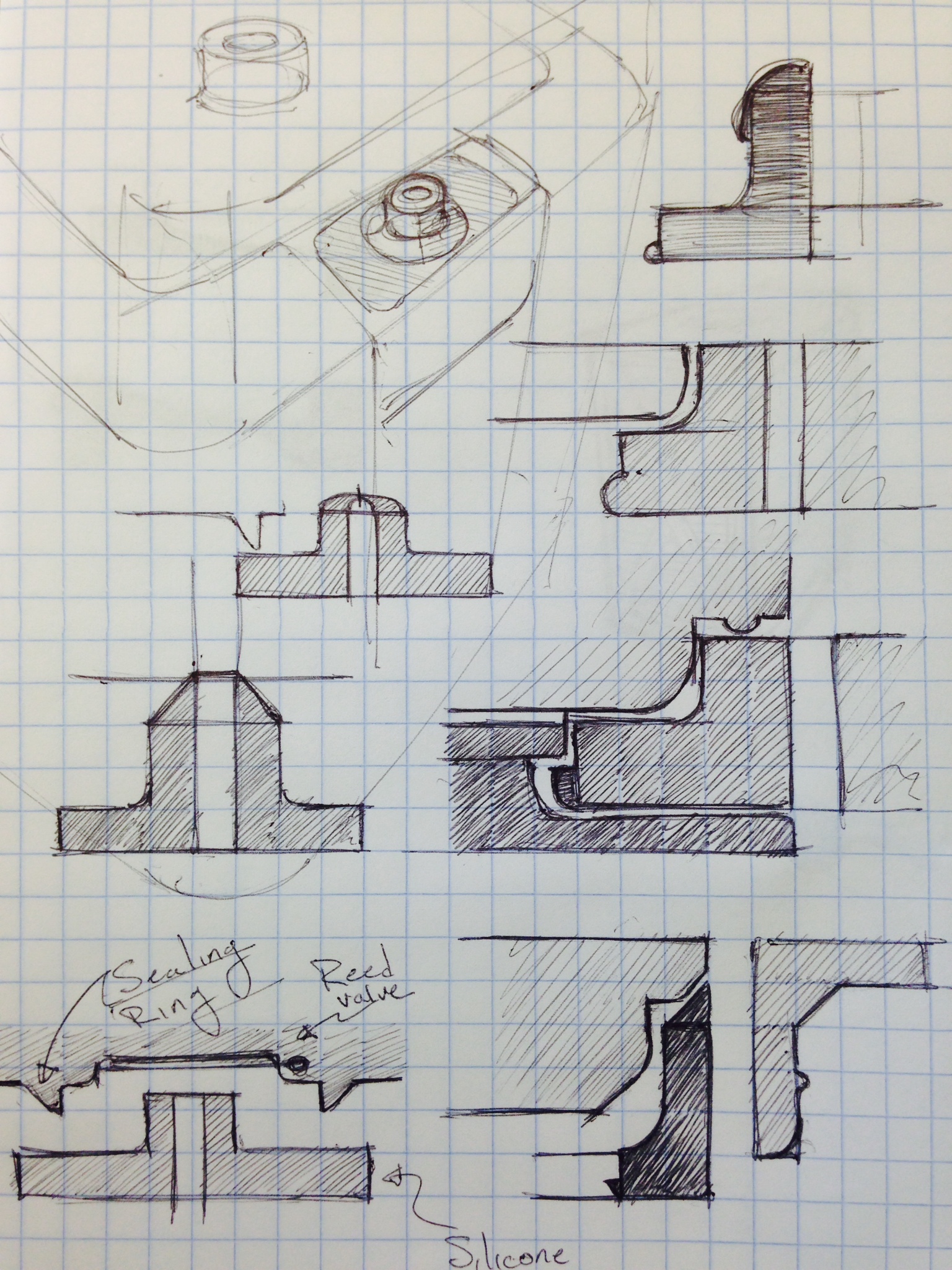

Design and Testing

A big part of what we are doing while at MassChallenge is working on the design and function of our prototype.

On the Design front our Chief Designer is sketching out the bones of the unit before we create it in virtual space using the suite of services that AutoDesk has donated to our team as MassChallenge finalists. Here is a sneak peak at what some of the sketches looks like.

While the design process is moving along we also at engaging in materials testing to hone in on the best construction elements to maximize the cooling potential and durability of the unit. This is a dirty process that can lead to a case of "Smurf Hands" (technical term)

Stay tuned for updates and progress reports!

Getting Started at MassChallenge

The Evaptainers team had been selected as a MassChallenge finalist and are getting settled into our new offices here at MassChallenge. We have big plans for the coming months so please keep an eye on our blog and we will keep you updated as we continue our work to bring our technology to market. We are very excited and look forward to sharing our journey with you!

Moving into MassChallenge

We here at Evaptainers are very excited to be among the 2014 MassChallenge finalists. We are in our new offices and getting everything setup to bring our technology to the world. Stay tuned for updates!